Paint Refinish System

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam

Paint Refinish System

Good to Know About Spot Repair and Finishing

What is denibbing?

In automotive manufacturing and refinishing, after a coat of paint or clearcoat has been applied, there is a chance that small imperfections such as dust nibs become embedded in the surface. With careful sanding and polishing of the spot in question, the surface imperfection can be made to disappear, without the need to refinish the entire panel.

Why is the abrasive quality important?

Every sanding step should make the following step easier. With a consistent scratch pattern, the sanded spot is far easier to polish out, making it impossible to see where the imperfection once was.

What do you choose dry sanding?

Our dry sanding system is a breakthrough in super fine sanding and scratch remove technology, results in that allows true topcoat sanding without the use of water. Thanks to the blocking effect of our interface pad, dust and nibs can now be located and removed faster than ever. With speed like dry sanding and finishes like wet, our dry sanding system scratches are extremely uniform and shallow, they can be easily removed by light compounding. If you are concerned with your topcoat finishing but prefer not to wet sand, the perfect system is this!

Sandwox Paint Refinish System

Abrasives For Dry Sanding

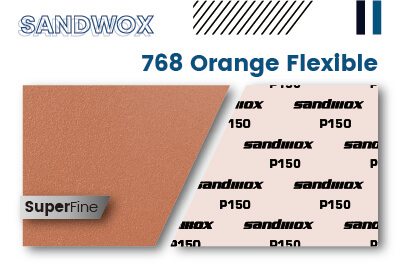

768 Super Fine Abrasive

Learn more about

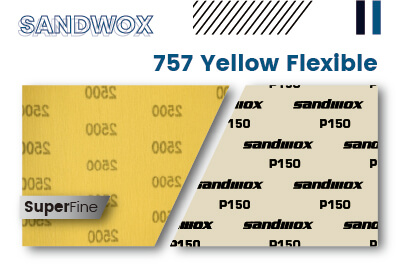

757 Super Fine Abrasive

Learn more about

918 Super Fine Foam Abrasive

Learn more about

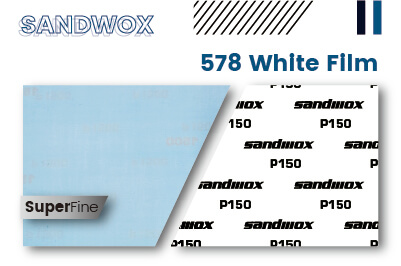

578 White Film Abrasive

Learn more about

CW74 Wet & Dry Sanding Sheet

Learn more about

CW54 Wet & Dry Sanding Sheet

Learn more about

CW34 Wet & Dry Sanding Sheet

Learn more aboutAutomotive Polishing And Finsihing

The perfect finish goes all the way to the smallest details. We are prepared to help you give your full attention to production and refinishing. Removing imperfections from painted surfaces requires a skilled hand, but also a high-quality abrasive that gives a consistent finish, together with our polisher. Sandwox spot repair abrasives work consistently on top coats, lacquer, clear coat and composite, making imperfections disappear while remaining sharp for a longer time.

SANDWOX 8150 RATORY POLISHER

Featuring a high torque motor, compact design, premium ergonomics and a lightweight housing, the LH 19E is one of the most capable and maneuverable rotary polishers on the market. Its lightweight and powerful design makes it the ultimate rotary polishing solution for a variety of industries including automotive detailing, collision repair and refinish -ing, marine, and more.

Learn More About 8150 Polisher

3D ACA X-TRA COMPOUND AND FINISH

Fast cutting, long buffing cycle, zero dusting and easy wipe-off – what’s not to like? Plus, 3D’s exclusive and even exotic Alpha Ceramic Alumina abrasive technology does not retain heat like conventional abrasive technology. This helps to keep surface temperatures low.Low buffing temperatures are important because unlike the misinformation that floats around the internet, heat is not good for clearcoats. You’re NOT supposed to heat-up clearcoat paint as a part of any buffing process although some people teach this as an approved practice.Besides top-notch product performance, 3D keeps your safety as a top priority when formulating any product including all of our compounds, polishes, and all-in-ones.Here at 3D, we have NEVER used crystalline silica in any of our products and we never will. We make products that are safe for you and the environment.

Learn More About Polish ProductsFeatured Products

3D ACA X-TRA 500 COMPOUND

Learn more about

3D ACA 510 PREMIUM RUBBING COMPOUND

Learn more about

3D ACA 520 FINISHING POLISH

Learn more about

WOOL COMPOUNDING PAD

Learn more about

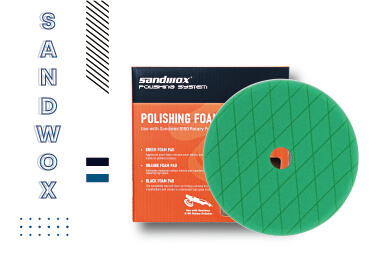

GREEN DIAMOND-CUT CUTTING PAD

Learn more about

ORANGE DIAMOND-CUT POLISHING PAD

Learn more about

BLACK DIAMOND-CUT FINISH PAD

Learn more aboutSubscribe

Want to be notified about our NEWS. Just sign up and we'll send you a notification by email.